“People get great results from track saws, which is what we’re covering—complete with a demo—in today’s discussion and video.”

Trade education and workforce development are two initiatives we value highly here at Dunn Lumber, so it should come as no surprise that we have close ties with Seattle Central College's Wood Technology Center (WTC). With roots dating back to the early 1900s, WTC's history intersects with ours at Dunn Lumber at various points (our very own Ed Dunn Jr. took some classes at Edison), and we're proud to be connected with such an exemplary educational institution.

Throughout the episodes in this series, we'll be speaking with Dave Borgatti, a long-time faculty member at the WTC, about the center's history, program offering, and various topics in woodworking education. Dave got his start in woodworking as a boat builder in Portland, Oregon, for Schooner Creek Boat Works, and ended up at WTC as an instructor in 1992. Since then, Dave has helped countless students—from boat builders to carpenters and cabinetmakers—learn the woodworking craft.

In today’s discussion, Dave and I go over when track saws are useful, if they’re worth the cost, and how to use them.

Watch our chat in the video above, or keep reading for a detailed recap.

The difference between a track saw and a circular saw

A track saw is a lot like a circular saw, but with a few added features that produce higher-quality cuts.

To make a straight cut with a circular saw, you’d need to create a fence to cut along using a scrap board and clamps. A track saw essentially has that fence built-in: It runs along an attached aluminum guide rail (or track), which engages the bottom of the saw to keep it “on track,” or in a perfectly straight line.

While they look similar to circular saws, you can’t use your circular saw in the same way—that’s because the foot on a track saw is designed to fit into the aluminum track, while the foot on a circular saw sits on top of the material.

Circular saws are generally more affordable than track saws, but they won’t give you the long, smooth, and super-straight cuts that a track saw makes possible.

3 benefits of using a track saw

Precise cuts

The biggest benefit of using a track saw is the precise, straight cut they produce. If you’re cutting long lengths or need an exact, straight cut, like to create a filler piece between a cabinet and a wall, a track saw will get you more precise results than a circular saw or even a table saw.

Minimal tear-out

Track saws also have a piece of plastic on the leading edge that acts as a built-in splinter guard, minimizing any tear, even when making cross-grain cuts.

Dust control

Well-designed track saws often have a vacuum port built-in, which extracts dust as you cut. This is especially useful when working on a job site or in someone’s home instead of a shop.

How to get straight cuts without a track saw

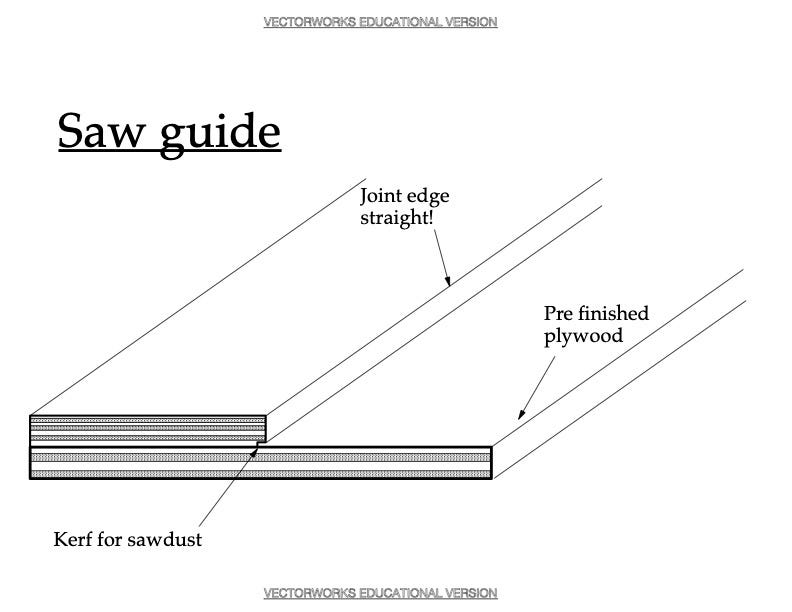

If you don't have access to a track saw, Dave suggests making your own saw guide. Joint a piece of ½” plywood dead-straight, then attach it to a wider piece of ½” pre-finished plywood. The shoe of your saw should slide easily on the slippery surface. You can make several guides at different lengths using this approach.

How to choose the right brand of track saw

There’s a wide range of options when it comes to finding a high-quality track saw. Most brands offer a very high-quality, consistent tool. As long as you choose the right blade for the type of material you’re cutting, you can expect a clean, straight cut.

How to use a track saw

The best way to learn how to use a track saw is to see it in action. If you haven’t watched it already, play the video above to get a full demo. Dave starts showing how to use the saw at the 7:05 mark.

Interested in learning more? Check out other posts from our introduction to the Wood Technology Series, like these covering how to calculate board measure and how to turn rough lumber into S4S material.