“Different lumber retailers measure and price their products in different ways, so it’s important to have a grasp on board measure, even if you have a good calculator on-hand.”

Trade education and workforce development are two initiatives we value highly here at Dunn Lumber, so it should come as no surprise that we have close ties with Seattle Central College's Wood Technology Center (WTC). With roots dating back to the early 1900s, WTC's history intersects with ours at Dunn Lumber at various points (our very own Ed Dunn Jr. took some classes at Edison), and we're proud to be connected with such an exemplary educational institution.

Throughout the episodes in this series, we'll be speaking with Dave Borgatti, a long-time faculty member at the WTC, about the center's history, program offering, and various topics in woodworking education. Dave got his start in woodworking as a boat builder in Portland, Oregon, for Schooner Creek Boat Works, and ended up at WTC as an instructor in 1992. Since then, Dave has helped countless students—from boat builders to carpenters and cabinetmakers—learn the woodworking craft.

Today, Dave and I dive into the topic of board measure—what it is, why we use it, and how to calculate it. We’ll provide an introduction to the concept for those who aren’t familiar, and share calculation tips and lumberyard stories along the way. Whether you’re brand new to board measurement or a seasoned pro, there’s something for everyone in this episode.

Watch our discussion in the video above, and read below for a detailed breakdown of our calculations.

What is board measure?

Board measure is the measurement of a volume of lumber. The unit of measurement we use to talk about board measure here in the U.S. is "board foot," or "board footage." In other parts of the world—Canada, for example—they use cubic meters to measure lumber volume.

A scenario in which you might need to calculate board measure is when purchasing hardwood for a project. For example, you might use a cut sheet to calculate how many board feet of lumber you need to order.

Why do we need to reference board measure?

You might be wondering why we need to calculate board measure if lumber comes in standard sizes like two-by-four or two-by-two. Standard lumber sizes have been milled to a specific size to control for variables in the shape and size of the wood. Because those sizes are consistent, they can be priced per piece.

When you visit a specialty lumber supplier, you may not find the standard selection of two-by-fours or two-by-twos. Instead, you’ll find a wide range of minimally milled lumber and live-edge slabs of wood with a lot more variability in size and cut. Because these pieces aren’t all the same shape, we measure them by volume.

Think of it like buying packaged goods versus buying in bulk—packaged goods are sold in a standard size at a standard price, while bulk goods are sold in flexible quantities priced per unit of weight or volume.

How do you calculate board measure?

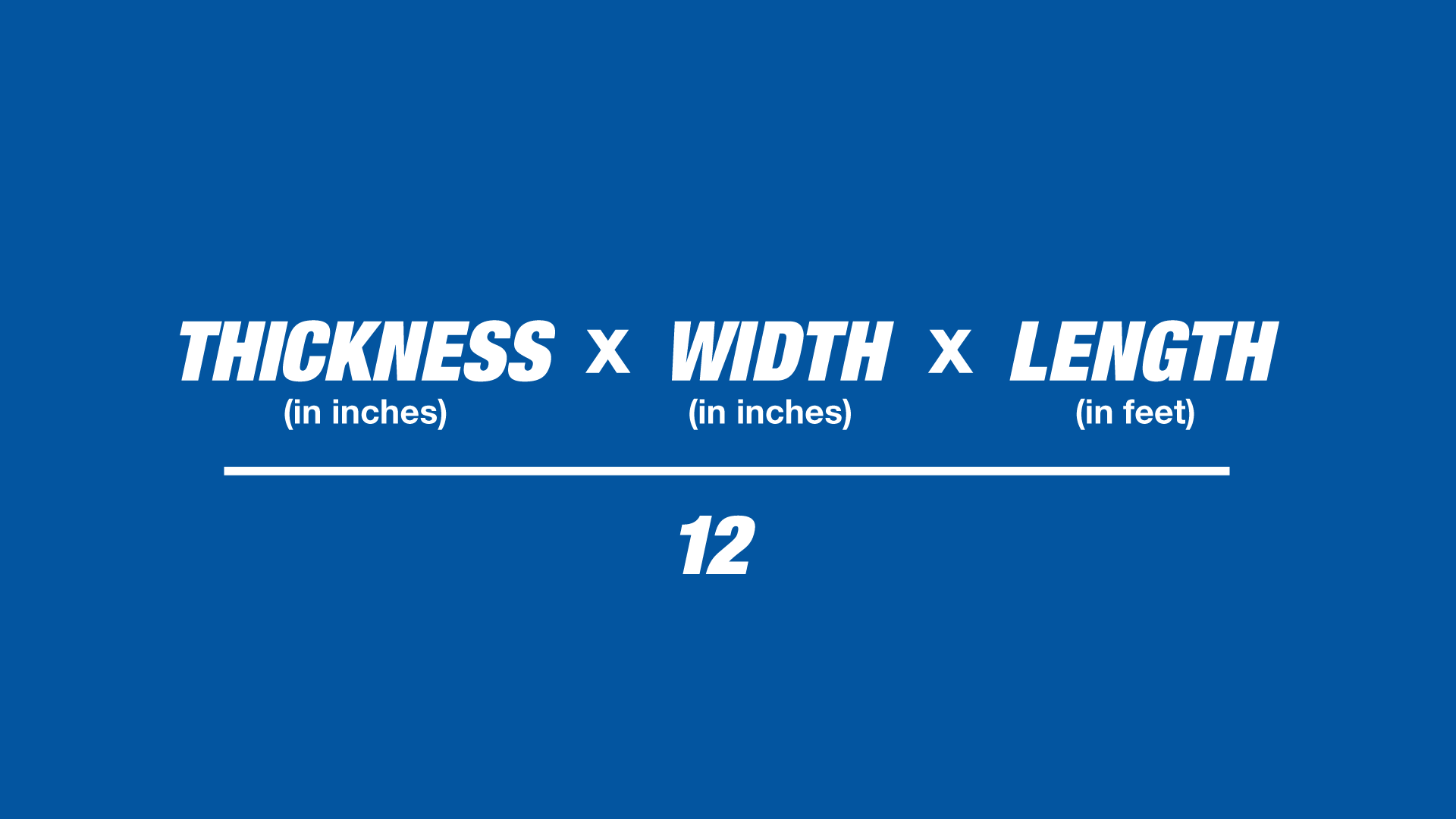

To find the board footage for a piece of rough lumber that isn't a standard size, simply measure the thickness, width, and length of your board, then follow this formula:

Calculating board measure for standard nominal sizes

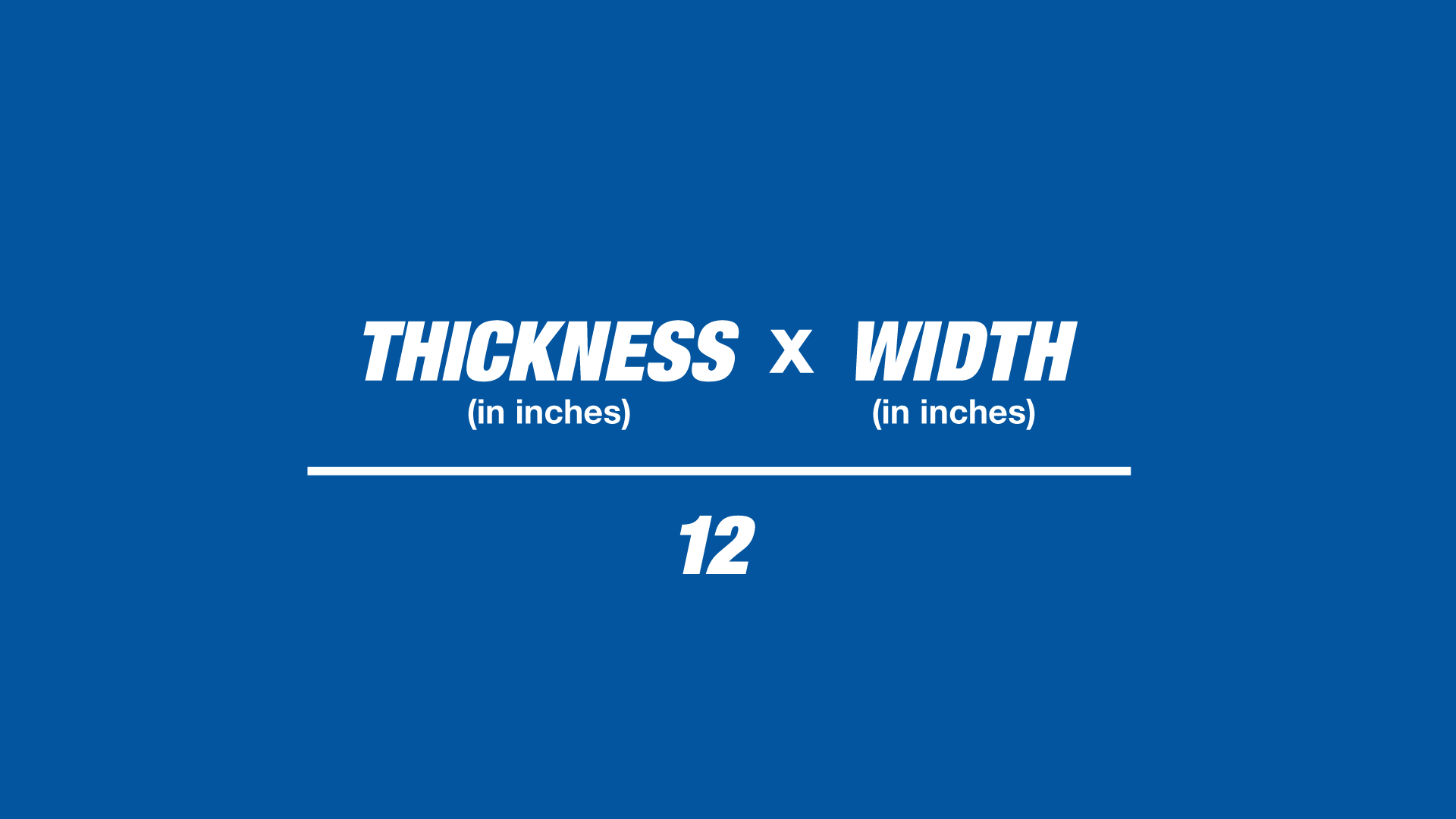

Here's a trick we use at Dunn Lumber to calculate board measure for standard lumber sizes. First, calculate board measure for a length of 1', then multiply the resulting number by the overall length.

For example, let’s say you have a two-by-four measuring 8’ long. First calculate the board measure as if it were 1’ long:

- 2 x 4 ÷ 12 = 0.667 board feet

Then, multiply that number by the length of your board in feet:

- 0.667 x 8 = 5.33 board feet

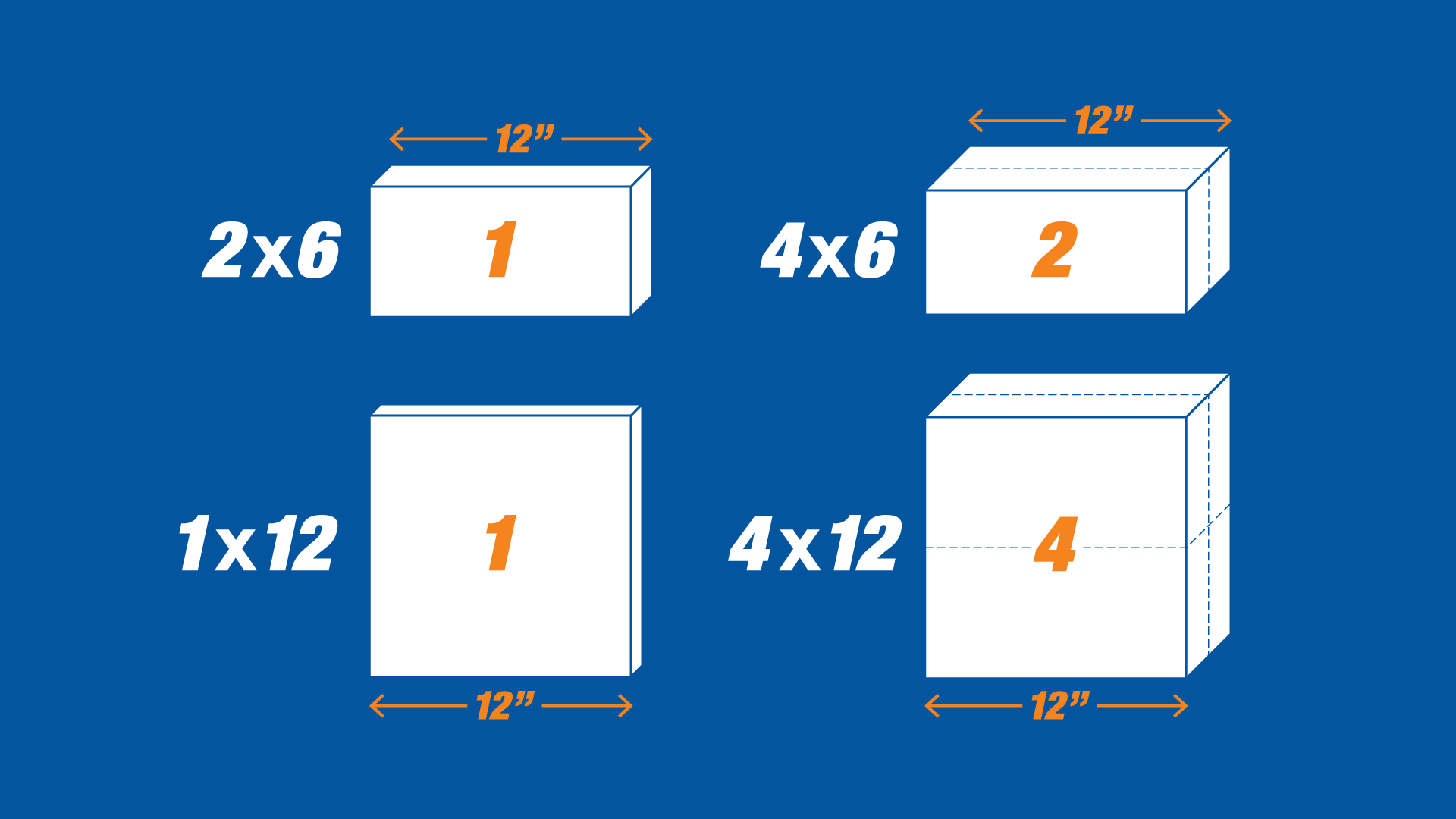

To make things even easier, you can memorize the multipliers for standard lumber sizes:

- Two-by-six - 1’ = 1 board foot

- One-by-twelve - 1’ = 1 board foot

- Four-by-six - 1’ = 2 board feet

- Four-by-twelve - 1’ = 4 board feet

How do you calculate board measure for sheet goods?

Rather than measuring by volume, these panel products are measured and priced “per mille,” or per 1,000 square feet. To figure out the price of a given panel, first calculate the price per square foot. (Since panels are priced per thousand square feet, simply move the decimal point three digits to the left to find the price per single square foot.) Then, multiply by the square footage of the panel (length in feet x width in feet).

Let’s say you need a four-by-eight panel that costs $7,361 per mille:

- $7,361 per mille = $7.361 per square foot

Now, find the square footage of your panel and multiply by the price per square foot:

- 4 x 8 x 7.361 = $235.55 for a four-by-eight panel

Nuances with board measure and pricing

Different lumber dealers measure, categorize, and price their products a little differently. (For more color on this, check out our conversation with Paul Mackie on how western red cedar is graded.)

For example, rough hardwoods or live-edge slabs don’t come in perfectly rectangular shapes, making it difficult to calculate board footage. Different lumber yards have different methods to work around this, and depending on the market price of the variety of wood, they may calculate and price differently than the next retailer.

At the end of the day, the best way to navigate around these nuances is to ask questions and compare the quality and pricing of lumber products from different retailers.

Interested in learning more about lumber sizing? Be sure to check out our most recent episode with Dave where we learn the difference between nominal and actual lumber sizing.