"Knowing how much everything has changed in the time since we first opened our doors, I thought it would be fun to take a look back with my dad (and Dunn Lumber's president), Mike."

In 2017, Dunn Lumber is celebrating 110 years of business. Even as I say that, it's hard to believe! In 1907, when Dunn Lumber was founded, the world looked totally different: Theodore Roosevelt was p-resident of the United States; Seattle's Pike Place Market opened for business (UPS was founded that year in Seattle, too); and the Chicago Cubs won the World Series (they also won in 1908, before heading into their 108-year drought that ended with their World Series win in 2016).

Knowing how much everything has changed in the time since we first opened our doors, I thought it would be fun to take a look back with my dad (and Dunn Lumber's president), Mike. I sat down with him to talk about the past century at Dunn Lumber, and an excerpt from our conversation is below. In it, we talk about what the company means to each of us, my dad remembers his first job at Dunn Lumber, and we open our cabinet of mementos to take a look at some of the items that were floating around the store back in its early days.

On First Roles

Mike:

I started sweeping, stocking, and cleaning. I might have been 16? I'm not sure when I actually started on the sales counter, but it was a couple years before I graduated. Almost all of our employees start at the sales counter—because it's a great way to learn the products, learn the customers and their needs, and learn all the issues. The sales counter is where the rubber meets the road.

Kirsten:

I started at the quick-check counter at the Bellevue Dunn Lumber location!

On Mementos

Kirsten:

Dad, you've worked at the stores through a time when technology was quickly changing the world. Do you remember how technology became integrated at Dunn Lumber?

Mike:

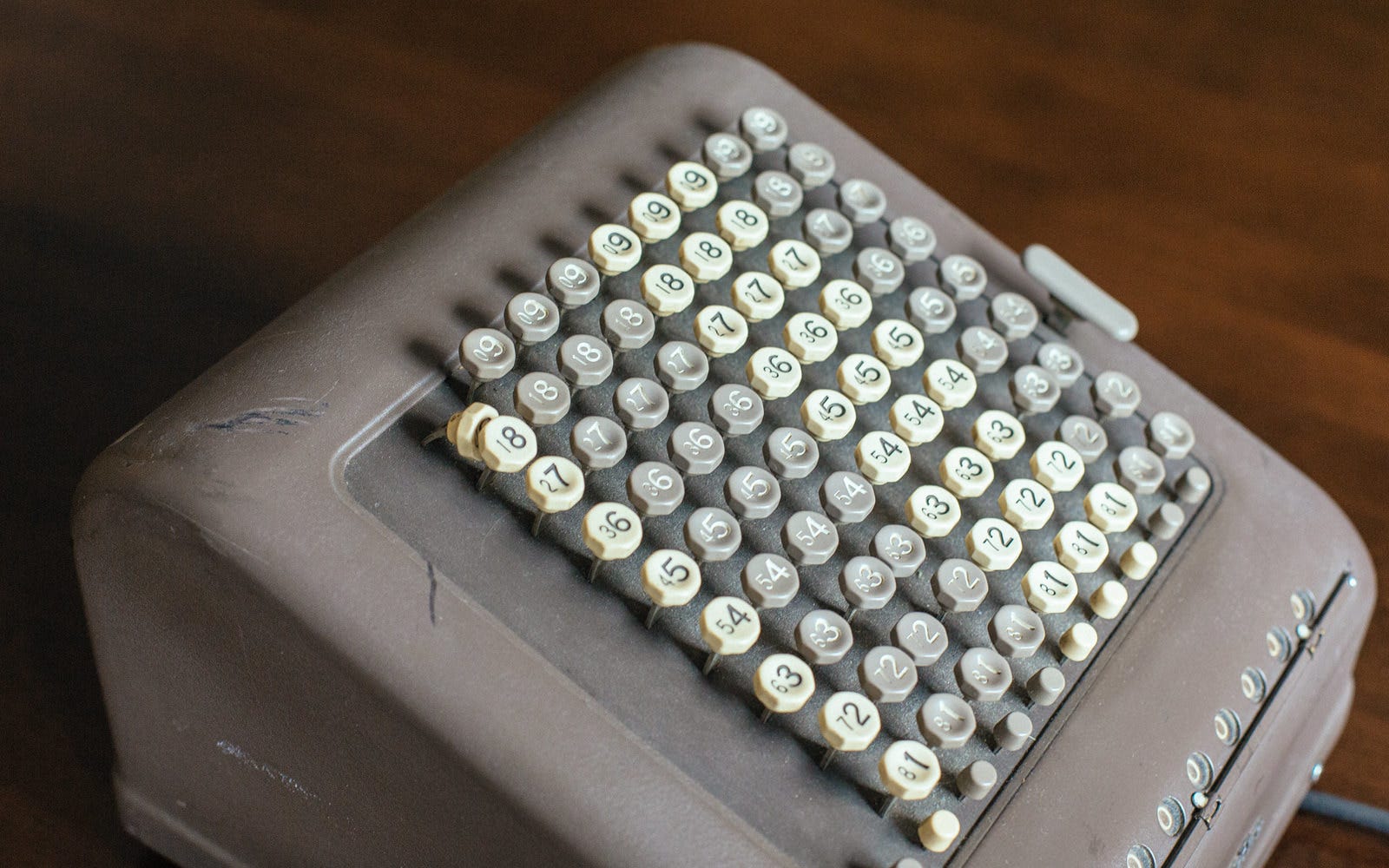

I got us to start using calculators. I had seen calculators and I said, “Guys, calculators wouldn't be very expensive."

Kirsten:

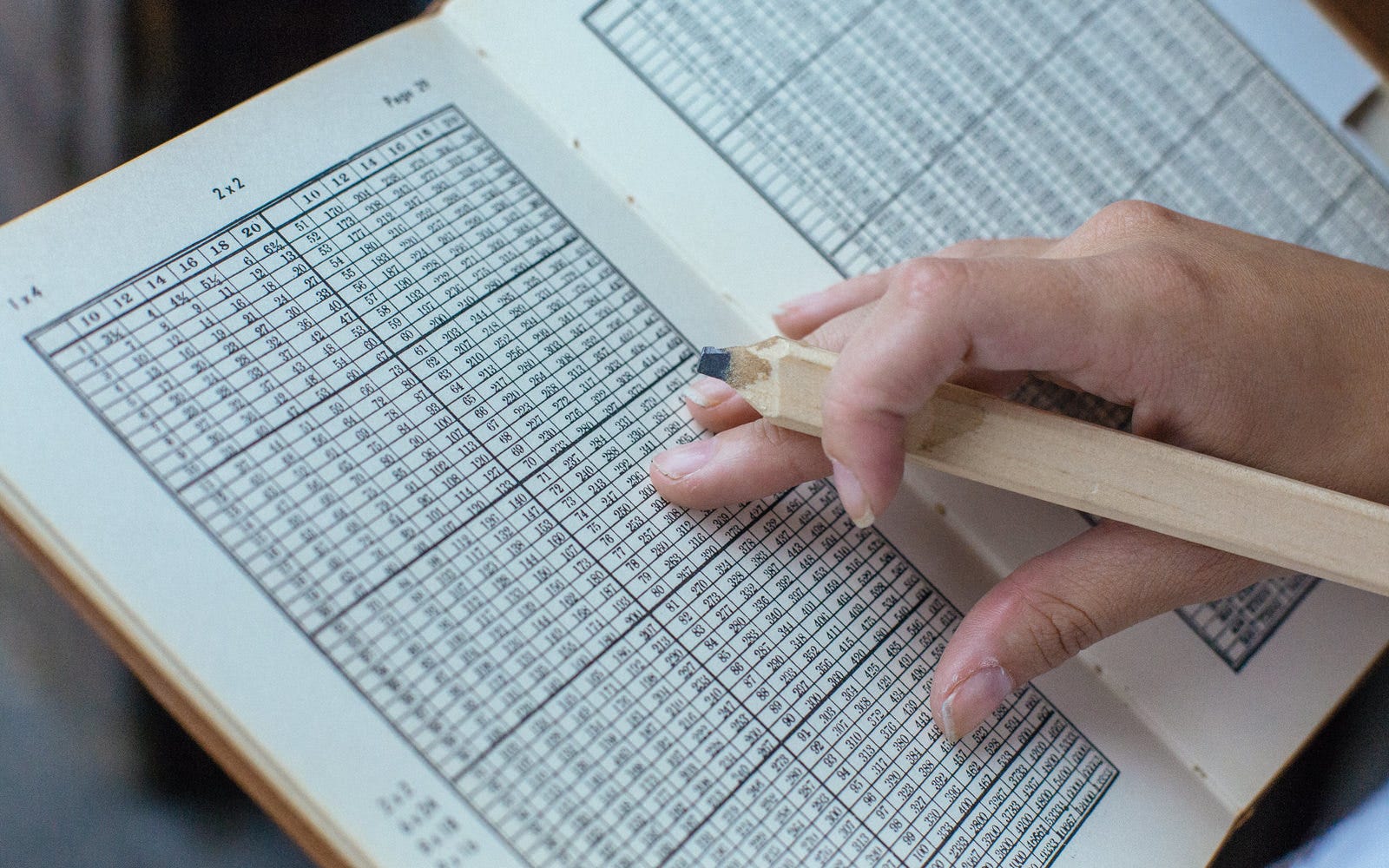

So, this is an ambidexter. Do you know what that is? According to the instruction book, "hundreds of lumbermen still prefer it to any other calculator that has since been published." Who publishes a calculator? That’s hilarious.

Mike:

The ambidexter was the precursor to the comptometer, which was the precursor to the calculator, which was the precursor to the point-of-sale system. The ambidexter is basically just a calculating guide; a cheat sheet for multiplication. When we first went to the point-of-sales system, they complained for about a week before they realized, "Oh my gosh. This is so much faster, and we don't make any mistakes." Can you imagine how many mistakes were made?

When I was at the Kirkland store I bought our first real copy machine. We had a copier in the corporate office that actually you had to take a transparency and put it on a piece of paper and then send it through, and then the transparency would come out with something on it that was sort of...you could sort of see a shadow on it. And then you would take that and put it on a piece of paper and send it through again on fuser mode and it would transfer to the paper sort of. We had six locations, and I bought six used liquid-based photo copiers.

The biggest change that happened when I came to work in the corporate office after I had managed the Kirkland store was—for the first time—we had enough labor to look into innovations in our purchasing. And so we started really listening to the contractors, because I had the bandwidth to do that—whereas my father didn't. He hand-wrote out all the price books, all the purchase orders, everything. The first thing I did was take his grid of pricing to a store called The Byte Shop in Westlake area (before Westlake Center), and I asked, "Can a computer do this? It's columns of numbers." The guy said "I think that's what's called a spreadsheet." And he gave me the first copy of VisiCalc for the Mac, and he gave me a Mac. He said, "Take this home and try it out."

So I go home and I open this thing up, and there's no manual. So I figure out if I click on the cell, then I can enter something into it. But try as I might I couldn't get it to add. Well what if I put 12 plus 12? No. Nothing. I tried all these things and I could not get it to add. So instead I just filled it all in as if it had added and then I took the disc to the Mac shop and I said "Can you print this for me?" So they printed it out on a dot matrix printer and I took it to my dad and I said "Look." And he said "Did it calculate these?" And I said "No. But it can." And he said "Well you better buy one."

So I ended up buying two Apple Lisa's, which was the predecessor to the Mac. But it actually was way more powerful than the Mac because it had a hard disk, and it had seven built-in programs, whereas the Mac everything was on a 128k floppy disc. The system software, the application software, and the documents were all in 128k. And you could have six, seven documents on one disc, 128k. A tenth of a megabyte.

My uncle Rob and I started putting all these things on spreadsheets, which gave us the bandwidth to add products. I started looking at what some of the yards were carrying that we weren't carrying, because the contractors couldn't get all this stuff at the box store. If we'd only had the things we had before and we hadn't upgraded the quality, it would have just been a matter of price, we would have lost all that business.

Kirsten:

What's with all the matches? In a lumber yard? That would never be allowed today!

Mike:

I remember seeing [lighters and matches] when I was a kid. From the logo you can tell that [the matches] were from an earlier time, because it's pre-Danny Dunn. I don't know what year that is. Everyone smoked back then; I mean, they smoked on the sales counter on either side. So back even in the 1970s, the counters were full of ashtrays full of cigarette butts.

Kirsten:

What can you tell me about this moisture meter?

Mike:

It was Grandpa Ed’s [Ed Dunn]. These two metal prongs measured conductivity between the two points. If there was more conductivity, there was more moisture. Back in the day there wasn't the tight lumber control standards, or grading agencies watching over mills. You've got to know whether or not it's dry, because if you tell your customer you're selling dry lumber and he puts it in his job and his wall tweaks because it wasn't dry, or he comes back and says, "Hey. I had a problem with this; Your lumber isn't dry," you've got a way to show him it is.

You don't buy your lumber bone dry, because it wouldn't stay bone dry—it eventually conditions to whatever its environment is. Normal construction lumber is dried to 19 percent moisture content. And if it's left outside, it will stay around 19 percent in this environment. If the sun's baking on it, it will begin to dry. If it's sitting inside, it'll begin to dry. One of the problems with buying lumber from a heated box store is that the dryness of the store is drying it at an unusual rate, and in ways that make the lumber twist and crack. It's much better to buy lumber that is stored in a cool, dry warehouse where it can dry naturally.

Today’s moisture meter is really for detecting moisture in your wall (or under your floor), but it also works for lumber.

Mike:

The whole "Pay Cash, Pay Less" cash slogan was the depression-era promise that customers' money would go a long way; that they would enjoy the savings of us not taking credit; they get more for their money by paying cash.

In 1928 we had a store behind University Village and people had in-store credit. But when Dunn Lumber moved to the north end of Lake Union, they made it strictly cash, because they were having a hard time collecting on debts, and it was the depression.

The vault came with the purchase of this location around 1930. And then when the fire came in 1938, that's when the building was replaced. And the only things that was left after the fire was the vault.

The Legacy of Trust video tells that it was our cash in the vault from the day before, with all the important papers, stock certificates, and stuff from the owners, including their own personal papers and so forth.

On Legacy

Kirsten:

There have been a few moments where I’ve asked myself, "How did this happen?" I don't remember choosing to care [about Dunn Lumber]. I think so much of it has to do with growing up in the company—even though I didn't grow up knowing much about what was going on in the business side of things. It’s been watching my dad, grandpa, and people in my family invest in this place. It's infectious. Plus, there's nothing more nostalgic than the smell of cedar when you walk into the store.

Basically, dad, it's your fault I care about this.

Mike:

I think it comes from caring more about the company than what people think of you, and being willing to pay that upfront because the company means that much to you. You grow up in it and you want to see it thrive. You know that just like generations change, companies have to change over time. And you see what happens when they don't. ...It takes an imagination. But if you're born with an imagination and enough care for the company that you're willing to risk, you're going to push things forward.

Kirsten:

I think it's really hard to not find pride in a company that is so well loved. I mean, anyone in our family will tell you that when people hear that we're associated with Dunn Lumber or when people hear about Dunn Lumber and don't know that we're associated with it, there's always praise. It's always positive.

Mike:

And how did we ever earn that kind of [love]? If you've got it, you sure don't want to lose it. Trust is hard to earn and easy to lose.

A Final Note from Kirsten

I've heard that a third of companies don't make it to the second generation, and half of those that do will end before the third generation. I think that's because the first generation is the generation that starts it; they're the ones with the vision and the excitement, and by the time it gets to the second or third generation, there's often obligation—they feel confined, they don't have the same vision their parents or grandparents had. With my generation, Dunn Lumber has fifth-generation family members working for the company. I believe Dunn Lumber is in a transition period of bringing the company into the next generation and making it relevant and meaningful to that generation—making it something we relate to and we're excited about. I remember the 100-year anniversary and how significant that was, because it's such a big number and was such a point of pride for my entire family. I think what's really exciting about 110 years is it represents the coming in of the fifth generation; of me working here, and my siblings and cousins, and watching the company begin to include the fifth generation and begin that transition of ownership. It's such an amazing thing. There are always points in a family business where you think, maybe we're not going to make it; maybe this is the end of the legacy. To be at 110 years and be able to see down the road and think, no, this is going to keep going. We might be here at 200 years. To have that perspective today is so exciting. It makes me proud.